It is well known that the temperature affects the mechanical properties of all polymeric materials. And of course not all of them behave the same way under the same thermal conditions. While some are very sensitive to temperature, others are not.

In the case of glass laminates, where the polymeric films are used as interlayers, the mechanical properties of the interlayer are key for the quality of the laminates.

The temperature is a setting parameter that controls the transformation processes of the glass interlayer films during the glass lamination process. The robustness of the laminates are directly dependent on the temperatures and how they have been controlled.

Not just that, it is very important to take into account the environmental conditions. That is because the mechanical properties of glass laminates are not the same when the laminates are at -10ºC than when they are at 40ºC at different. Therefore we should remember that the physical properties of the glass interlayer film, such its stiffness and hardness, are temperature dependent.

More important than the temperature level are the cyclic fluctuation ranges of temperatures between different days. The daily delta temperatures force the laminates to suffer, a non visible but continuous, mechanical elongation and contractions phenomena. Daily temperature fluctuations between -15º to 5ºC, or between 10º to 30ºC, or 20 to 45ºC might generate different levels of stress to the films. These shrinkage and extension movements inside the glass might generate undesirable displacements at the edges of the laminates helping the entrance of water. A small pore may allow to entrap water at the edge and promoting its displacement inside by capillarity favoring the start up of a delamination process. At this point the degree of ambiental humidity becomes also an important factor affecting the laminates.

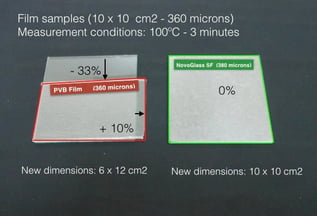

At NovoGenio we have studied carefully this stressful situations, analyzing and comparing the behavior of the PVB film to the NovoGlass SF film. Our work has been focused on:

- - The 3D elastic free movement of films

- - Elastic behavior of films under tension at 70ºC and their recovery capacity

- - Creep test of laminates between 70º-110ºC

If you want to get this free report, you can download it.

CATEGORIES:

Glass and Polymers LaminatesSeptember 28, 2014