Until now the TPUs used for Ballistic Glass Resistant constructions have been considered just adhesive films. These TPUs have been appreciated just for their optical transparency and their adhesion properties.

But here it is the question: are they just Adhesives or could they play also structural roles?.

In a previous paper ("Security and Ballistic Glass Laminates: Physics of Materials") we already listed some other important contributions to the Ballistic Glass Resistant structures before impact and when impact takes place.

In this paper we want to show that the TPUs can also play another important role as a structural elements, in some way similar to spider webs.

To reach the points of our subject we will need to start our discussion around the elastic and plastic properties of the TPUs. That is why we are going to focus ourselves around the Shear Stress and Strain measurements of materials and their plots. Be sure that in the "exercise" we are not going to use any sophisticated equations in our disclosure.

To make our discussion "more digestible" we want to start our approach of TPUs from the elastic-plastic properties of food. And, in order to facilitate our work we will use a food picture guide.

So, let us start.

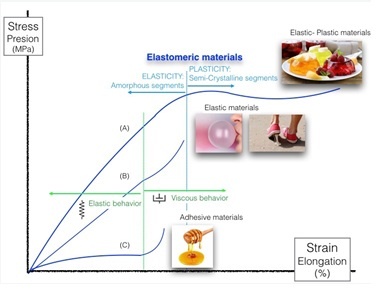

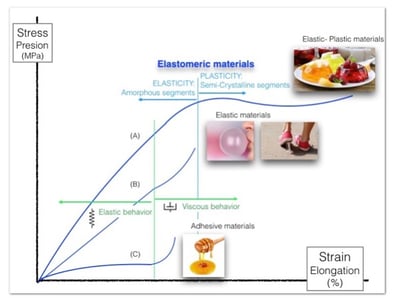

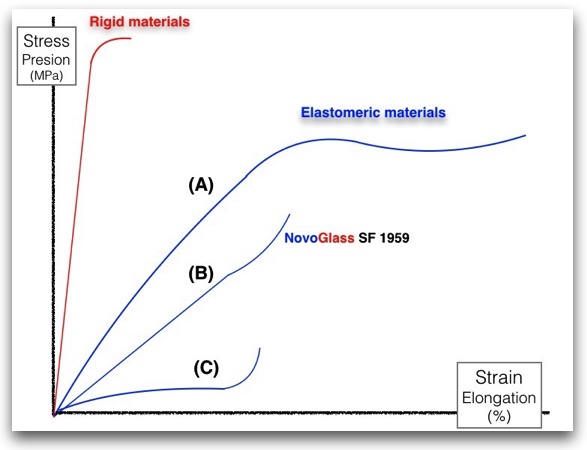

From materials point of view, and taking into account their elastic-plastic properties, we can discriminate between two main type of products: the rigid ones and the elastomeric ones. The following section presents them all in a graphic mode.

Tensile Stress-Strain graphs of Rigid and Elastomeric materials

This first picture aside shows the Shear Stress-Strain performance of the two groups of materials (food wise): the rigid ones and the elastomeric ones.

The rigid ones have almost no flexibility and break at high stress values, like dark chocolate bars do, sometimes with some extra effort!! They have almost no elasticity and low plasticity. They are "rigid".

By the contrary the elastomeric materials show some valuable properties based in their elongation properties before their breakage.

Thanks to them we can enjoy the plasticity of Jelly, honey and the chew gums. Our mouth, working as a sofisticated shear stress-strain equipment, helps us measure and valuate them mechanically. Fortunately it helps us also to enjoy their flavors. It is really a sophisticate machine with a complex pack of sensors on it.

Without leaving our food template, we are moving towards the materials used in the construction of the Ballistic Glass Resistant structures. Focusing our attention to the tensile stress-strain rigid ones we talk about their typical response to stress.

Tensile Stress-Strain graphs of Rigid Materials

The side graph shows, with no stress scale values on the y axis, that rigid materials of our interest: glass, polycarbonate and polymethylmethacrylates, break without almost no elongation. Rigid materials always have maximum stress values much higher than the elastomeric materials. It is clear that for impact resistant structures, the higher this value the better.

Observe that in the case of bullet impacts, when the rigid material breaks up, the energy used to break the rigid material is "stolen" from the bullet energy impact, reducing its further damage capacity.

The elastomeric materials suffer elastic and plastic deformations at lower stress. The profiles are also different between them.

Tensile Stress-Strain graphs of Elastomeric Materials: Amorphous and Semi-Crystalline

Moving now at the soft ones, like the PVBs and TPUs, their mechanical response is completely different, and not always the same, as we will see. In their case their specific differences are dependent on their molecular compositions.

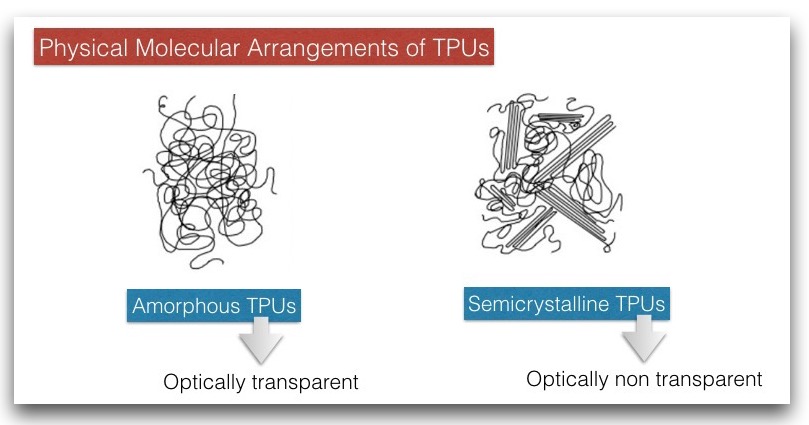

In the case of the TPUs, at molecular level, they are the results of combinations of diisocyanates, polyols and short length diols. All these components are arranged and distributed along the polymer chains in different orders and in different percentages. Depending on their final and specific chemical compositions it is possible to have TPUs with some crystallinity parts (organized molecular parts) or TPUs completely amorphous, without any possible molecular reorganization. The photo below shows how the two types of molecular chains might look like.

Depending on their molecular organization their mechanical response is different. In that case we can identify three types of curves: A, B and C as the below picture represents.

Materials with curves type (A) correspond to semi-crystalline materials, where the first part of the curve is mainly dependent on their molecular elastic components while the plateau part of their curve is mainly due to the molecular crystalline components. At the plateau the material elongates easily with a small effort but with no capacity to recover because its main elastic properties are over. That is because crystalline domains unfold and consequently break their crystalline structures.

Materials with curves type (B) are typical of elastomers with almost no crystalline domains on their molecular structures. These materials correspond to amorphous structures with a higher elastic behavior than a viscous behaviour.

Materials with curves type (C) are also typical of elastomers with almost no crystalline domains on their molecular structures, like type B. The main difference with (B) materials is that (C) materials have higher viscous behavior than elastic behavior, just like honey. These type of elastomers just can be used as base substrates for adhesives applications. That is, the viscosity advantage needs to be complemented with adhesive promoters to get the final adhesive material.

With these clasifications in mind, it is easy to conclude that the best TPUs to be used for Ballistic Resistant Glass constructions would be the ones that fit inside the materials of curves type (B) and (C). That is because these materials have to be optically "clear", that implies that they have to be amorphous, with almost no crystalline domains on them. And also they have to have an optimized mix of the elastic and viscous behaviors on them to have a good mechanical performance for the ballistic applications.

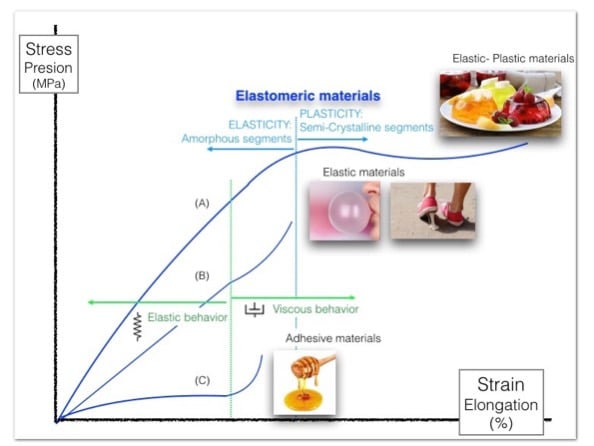

Elastomers type B vs type C Mechanical Properties

As a summary of all discussed until this point we can say that the TPUs that are used for security glazing applications belong to the group materials in which the elastic properties are more important than the plastic ones (materials with curves B and C). And after that let us discriminate between B and C.

To distinguish between these two, we have to make use of the elastic and viscuous components on them. Technically these two mechanical behaviours are represented by a spring symbol (the elastic) and by a dashpot (the viscous).

Type B materials have a mix of elastic and viscous behaviours. For impact resistant applications the elastic component is very important, because it gives to the elastomer material its structural performance. By the contrary type C has almost no elastic component, but it has a higher viscous component than type B.

Related to the adhesion properties, materials type C and B need from some adhesion promoters to ensure a robust material adhesion, building chemical bondings between them.

Conclusion

In other words, the type BTPUs do not behave just like adhesives, they provide also structural performance as added value. And of course, their structural performance could be very useful to improve the BRG (Bullet Resistant Glass) structures to get more resistance to bullet impacts.

You can get a more valuable impact resitant product if you use a TPU with not only adhesion and optical properties, also structural properties. The NovoGlass SF 1959 belongs to the type B of materials with added structural performance.

If you want to get more information about the structural values of TPUs, please do not hesitate to contact us.

CATEGORIES:

Security GlassJuly 10, 2016